Earth's own indigo: Using ethical and natural dyes

We are serious about sustainability. There is an increasing urge to act positively for the wellbeing of our earth, so we decided that 2019 will be our opportunity to be more committed than ever about helping the environment. This has become especially obvious while sourcing our new interior textiles. You can discover our latest Earth range here.

Have you ever wondered exactly who made your most loved items? How they live their lives? Who are they and what do they do? Well, we are excited to share one of our most recent experiences in meeting these individuals, and the incredible impact it has had on our future aspirations for INBALI.

To us, ‘ethically made’ means that there is no exploitation during the creation process of our furniture and interior decoration. No exploitation of human beings, no exploitation of animals and no exploitation of the environment.

It's all organic, the smell comes from the leaves slowly fermenting. Naturally dyed fabric doesn’t pollute the surrounding environment

We are fully aware of the impact that the textile industry—with modern production and dyeing techniques—can have on the environment if not properly controlled. Modern dyeing processes are incredibly toxic and extremely wasteful. A vast range of synthetic chemicals are used in the process of dyeing, setting and rinsing, often discharging harmful compounds and polluted run-off straight back into our ecosystem. We aim to continue the INBALI adventure with this constantly on top of our minds, and with the help of the oldest eco-friendly technologies we have found in Bali.

Colouring with the Earth's natural hues

While roaming some of the more hidden Balinese villages to bring you the best furniture and home decoration, we recently discovered something that will forever change our business values and future approach.

Amongst the rich patch-work of Gianyar’s rice fields lies one of the most incredible treasures we could have found. One of the oldest all-natural dye workshops in Bali. As the owner greeted us with a warm smile at the entrance of his small workshop, we knew this was the beginning of something exceptionally meaningful.

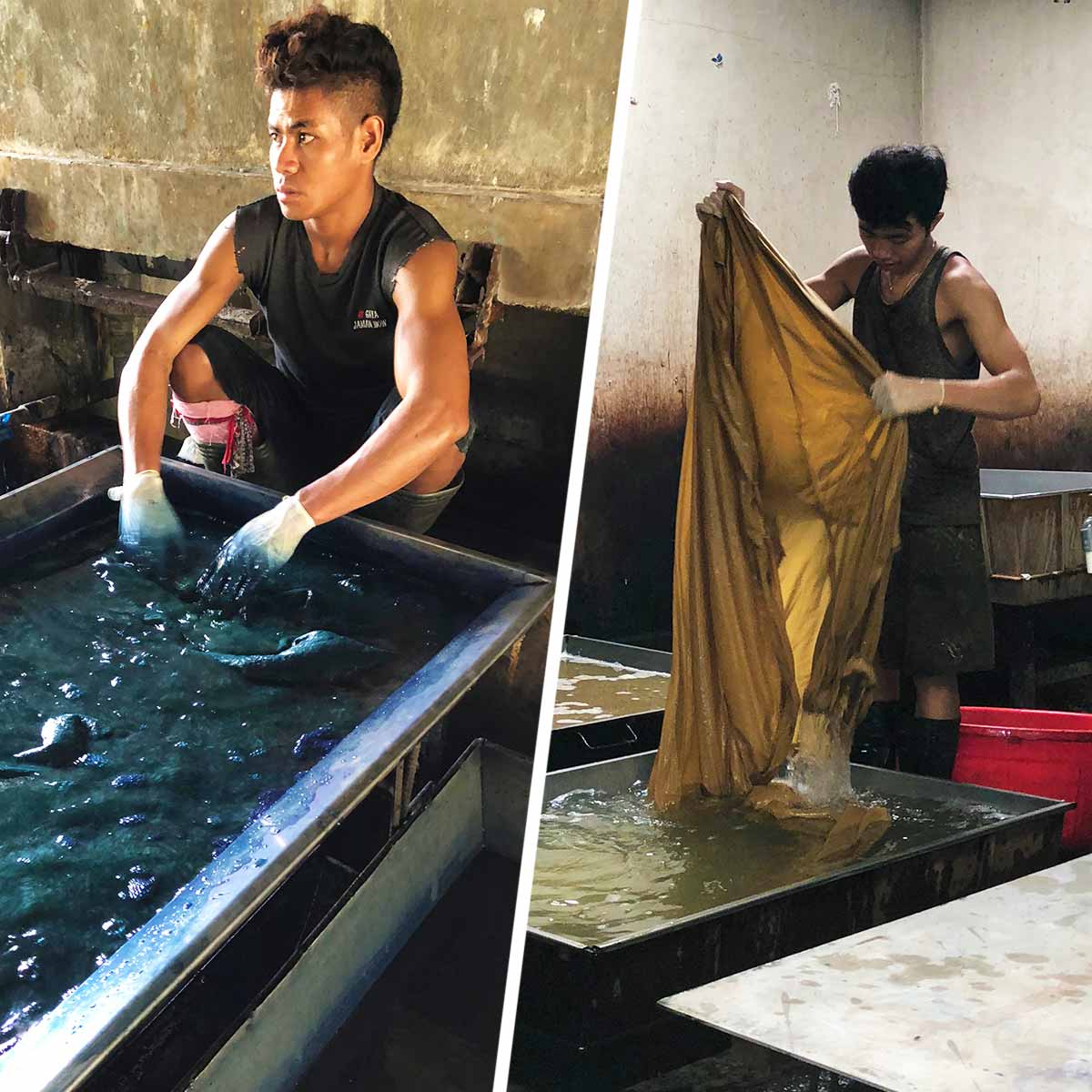

As we walked in, a strong herbal smell is the first thing that hits our senses. "It's all organic and from the earth, the smell comes from the leaves slowly fermenting". Stepping around puddles of blue dye, we watch the local craftsmen in awe. Dressed in gloves and boots, they methodically dip and knead sheets of hand-woven cotton, linen and bamboo fabric into vats of deep indigo. Massaging the fabric between their stained fingertips. These Balinese artisans create all of their botanical dyes from indigenous plants and trees. "Naturally dyed fabric doesn’t pollute the surrounding environment", says one of the craftsmen to us.

Ethical natural dyes

This highly impressive process of natural plant dyeing has been developed over thousands of years as a way of transferring beautiful colours from nature permanently into fabric. It was common practice to collect plants, herbs and bark to create dye baths in ancient India.

In the workshop, the beautiful earthy colours are extracted from various plant materials. Most of which are grown in plantations within just a few miles of the hidden studio. Yellow dye comes from mango tree leaves, while black is made from the young leaves of the 'ketapang', also known as 'umbrella' tree. Extracted on site, mahogany leaves provide natural browns. The most impressive colour, the striking blue, comes from native 'secang' trees and the leaves of indigo plants. By blending the five base colours of yellow, black, brown, red and blue, they create a whole spectrum of spectacular natural hues from the Earth.

While it’s been acknowledged that the most vibrant colours are derived from tree roots, we chose to work with this workshop that only use the leaves. We know that if the roots are used, then the tree would die.

The natural dying process

Once collected, the leaves are then finely chopped by machine. The ground leaf mixture is boiled in water for six hours until the dye is ready to use. Fabric is dip-dyed for an hour before being washed, and the process is repeated six to ten times depending on depth of the shade required.

Hung to dry under the hot Balinese sun, the excess dye runs off the fabric into a field of plants, cultivated specifically to filter the water before it runs into the river.

This dyeing technique is achieved completely by hand, which naturally results in slight colour variations and fading in areas where the natural colour may not have taken to the fabric 100%. By embracing these tiny imperfections rather than sacrificing it for a superficially perfect product, we together make a difference to our environment and our own wellbeing.

Sustainable and ethical textiles at INBALI

There is no better feeling knowing our interior fabrics are made sustainably. You can feel and smell Mother Earth, and you are making positive choices for your home at the same time. Today, the use of natural dyes is costly and time-consuming, with the entire process taking around 2 to 3 weeks from dyeing until drying. We believe this is the right choice though, and a necessary and positive step towards being sustainable.

From now on, we commit to our continuing search for natural alternatives to chemical processes here in Bali. This is why we are very excited to introduce you to our new organic range of interior fabrics naturally dyed from plants.

Our bespoke soft throws, table runners and interior batiks are designed and handmade by the craftspeople of our exciting new find—our dying workshop in Bali. We are proud to support an industry which pays such high regard to nature, tradition and quality.